Discover our Power Sealer line:

- Power Sealer

This no-nonsense Power Sealer forms the solid basis of the renowned Power Sealer line. The outstanding 5 mm sealing performance is achieved by a pneumatic bi-active and time-controlled impulse sealing system. Standard vacuum feature integrated.

- Validatable Power Sealer

This model is validatable and generates an 8 mm temperature- and time controlled seal. The validation enables that critical seal variables like seal force, seal temperature and seal time are being controlled.

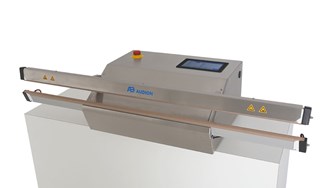

The Power Sealer TC is a high-performance temperature controlled sealing machine designed for demanding packaging needs in the high-tech and food industries. It features a durable stainless steel housing, touchscreen interface, and powerful bi-active and pneumatic seal bars that ensure consistent, airtight seals.

- Power Sealer PLUS

The next step in the Power Sealer line is the Plus version. With its unique and most precise system of validation it meets todays' most stringent packaging requirements. 8 mm Temperature- , time- and force controlled seal. Includes Audion Touch Techware.

- Power Sealer PLUS IP65

Our flagship model in the Power Sealer line. Especially designed for dusty, humid or regulated (clean room) production environments. Highly advanced validatable impulse sealer. An 8 mm temperature-, time and force controlled seal. Includes Audion Touch Techware. Also available in Bag-in-box configuration.

The Power Sealer XL has the largest sealing length of the Power Sealer range. With a sealing length up to 2500 mm it can effortlessly provide your largest products with customized packaging or protective covers by means of an 8 mm seal. Optional validation: temperature-, time- and force controlled sealing.

Unique steamsealer enabling bags to be sealed without electrical power supply. Instead, it uses pressurized steam to operate. suitable for explosive environments. 8 mm temperature controlled seal.