Products

AVM 190

Innovative and most compact vertical form fill seal machine on the market, operating at high speed

Interested in our AVM 190?

We are more than willing to support you with your request or run a demo with your packaging

Proven German quality for more than 40 years

The Audion AVM 190 is a compact high quality vertical form fill and seal machine equipped with an advanced servo drive, performing accurate bagging at high speed to reduce costs and reach your business goals.

The AVM 190 is designed to pack free flowing products like granules, powders, liquids and solids at a speed of 100+ bags/ minute.

The low machine height of 1200 mm facilitates easy access to the machine and flexibility in product feeding (both manually or fully automatic). The AVM features a PLC controlled sealing system for optimized seal integrity and high speed bagging, producing bag sizes up to 190 mm width and 300 mm length (max 2 liter/bag). Bag sizes can easily be adjusted from the user-friendly touchscreen. From this touchscreen interface the complete integrated packaging solution can be controlled (including eventual auger filler, conveyor belt and volumetric doser).

The Audion AVM 190 is available in two versions:

AVM 190 HS: High speed Heatseal for paper and foils (laminates, PP)

- Horizontal and vertical heat seal

AVM 190 HSI: High speed Impulse seal for poly film (PE)

- Horizontal impulse seal and vertical heat seal

Audion can supply the complete integrated packaging solution, including dosing- or weighing equipment and necessary discharge solutions.

By integrating the Audion AVM 190 you are ensured of:

- a sturdy and reliable pakaging solution

- a turnkey solution

- to streamline your efficiencies

- high precision due to servo drive

This makes our machine unique

We work together with you in providing the best quality packaging machines to help you grow your business

Tailored to your needs

No packing process is the same, we at Audion understand this. The AVM has a configurable construction in order to modify it easily to your specific requirements. We bring almost 80 years of experience to the table ensuring you to find the best suitable packaging solution together with you.

Intelligent machine - Turn-Key solutions

The Audion AVM is often integrated into a complete packaging line. Our drive is to implement it easily and quickly into your current packaging process. We have integrated all kind of intelligent features into the AVM in order to make this as easy as possible. Not only hardware - but also software related, all to make the integration as smooth as possible.

Ergonomic & Ecological proof

The clever design of the Audion AVM minimizes the film overlap in order to use the film as effective as possible. This results into a decrease of film consumption. The easy access allows you to clean and maintain the AVM easily and effectively. Both high volume batches as single products or low volume batches can easily be packed with the AVM. The optimized cleaning and maintenance features and reduced film consumption will give you great competitor advantages.

Made in Germany

Audion is a leading manufacturer of sealing equipment. It all began in 1947 alongside the famous Dutch channels. Today we have two modern production sites in the Netherlands and Germany were we construct packaging machines which are built to last. Focusing on the end-users' comfort and guaranteeing the best, save and most reliable outcome.

Videos

High speed without compromise

Speeds can range up to 100 bags per minute and numerous bag types and sizes are possible.

This makes the Audion AVM 190 one of the most universal and flexible vertical form fill and seal systems on the market.

The construction is smart and compact and can easily be integrated with a weighing unit like multi head weigher, auger filler, linear scale of volumetric cup dosager.

To sum up:

- User-friendly touch screen

- Quick return on the investment

- Reduced film consumption

Benefits

The Audion AVM 190 gives you the following benefits

- High speed performance:

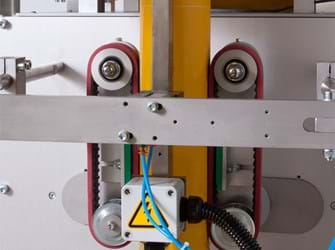

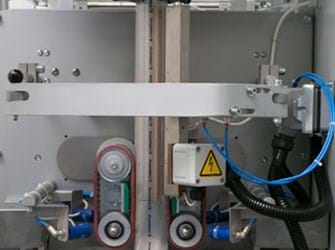

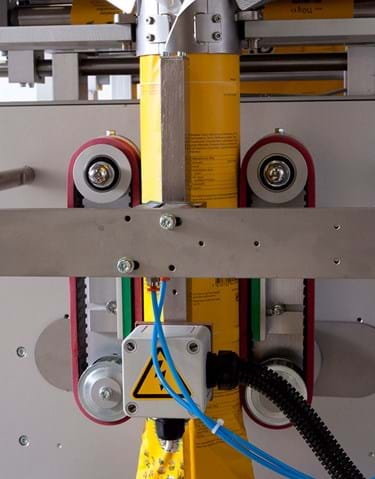

- The powerful servo drive performs precise bagging at high speed, maximizing your output.

- Low height of the machine:

- Less than 1200 mm, meaning that product feed can be done manually or by means of a fully automatic dosing system.

- High flexibility:

- The compact height of less than 1200 mm, meaning that product feed can be done manually or by means of a fully automatic dosing system. Further, the integrated servo drive ensures fast film transport and full flexibility in terms of more fragile materials and accurate bag length.

- Product safety:

- All parts that are in contact with the product are made of stainless steel.

- Easily integratable in packing line:

- A wide range of optionals is available to customize your AVM set up communication with in and outfeed equipment

- Small footprint:

- Compact and sturdy design with a weight of just 250 kg.

- Quick set-up and low downtime:

- The special designed film reel holder accommodates a fast and easy film loading, ensuring a minimum loss of production time.

- Durability:

- Audion uses high-end components and industrial materials, standing for a long lifetime of your machine.

- High versatility:

- The AVM can pack a wide variety of products, such as powders, granules and parts, coming in a variety of shapes and kinds such as candies, coffee beans and snacks etc.

- Easy maintenance:

- The AVM is designed and constructed to facilitate easy cleaning and maintenance. Form shoulders and wearing parts like knives can easily be replaced to minimize downtime.

- Automatic jaw release:

- If a product is trapped between seal bars the seal bars are automatically released

- User-friendly control panel:

- Operation can be controlled by one integrated control panel, facilitating job storage , batch counters, statistics, log-in levels, up to 50 recipes.

- Quick problem solving:

- The self-diagnostic info system ensures quick problem solving and minimum downtime.

- Mobility:

- The mounted casters facilitate optimized mobility.

- Fin seal possible:

- AVM facilitates to produce a fin seal. Ideal for film materials that cannot be sealed (this material should be provided with a coat layer that can be sealed inside)

- Photocell for pre-printed film:

- The AVM standard integrates a photocell for pre-printed film.

- Hygienic design:

- Quickly and easy to clean

Options

The following options are available on the Audion AVM 190

- Two versions:

- High speed for laminates and PP (HS) and High speed Impulse for PE film (HSI).

- Gas flush:

- Injecting a gas before the sealing phase increases the product's shelf life, it offers extra protection and it prevents the product from colouring.

- Support table:

- Needed for bags more than 1,5 kg.

- Dust extraction:

- Prevent dust from coming between the seal bars, advisable when packing dusty products like powder.

- Product catching plates:

- Break the fall of the products and therefore protect the product and the bag.

- Central web tracking:

- Automatically keeps the film in the middle of the format shoulder.

- Air press device:

- Removes the air out of the bag, mounted above the seal bar.

- Double stroke including heightening:

- To create a longer bag.

- Twin seal:

- To pack liquid products.

- Hole punch:

- Round, euro or carrying handle.

- Quatro seal:

- Produces stand-up bags with square base and four sealed sides. It is suitable for packing a range of granular products, particularly suited for products that require high standards of package, without any wrinkles.

- Photocell or Window sensor:

- To give the AVM a start signal for activation.

- Product vibrator:

- To spread the product through the bag.

- Motor driven film reel:

- Additional support to accelerate and decelerate of heavier film rolls.

- Non-stick device:

- Prevent bags to stick to the seal bar.

- Static eliminator:

- Prevent dust from sticking to the foil, advisable when packing dusty products like powder.

- Foot pedal:

- Recommendable for manual operation.

- Various shoulder formats available:

- Audion has various shoulder formats available to produce different bags.

- Various coding options:

- A thermal printer or labeler is available to provide your bags with a clear print.

- Dosing systems:

- A wide range of automatic dosing systems is available to optimize your product feeding with the AVM 190 HS(I). Multihead scales, various auger or pump systems, depending on your products’ characteristics.

Package styles

The following bag types can be created with the AVM 190

- Pillow bag:

- As per the name of the bag, it forms the shape of a pillow. Once filled, it balloons from the middle and flattens out at the top and bottom seals. Pillow bags are most commonly used for single serve products.

- Block bottom bag:

- Blockbag bags are characterized by their rectangular, flat bottom and insert in the sides.

- Gusseted bag:

- The bottom of a bottom gusseted bag is flat. The flat surface of the bag allows the pouches to stand without any external support. The gussets are designed in such a way that when the pouch is filled with a product, most of the product sinks to the bottom of the pouch - near the gusset.

- Chain bags:

- Bags which are sealed but still connected to each other

Specifications HS

More specifications of the Audion AVM 190 HS, High speed for laminates and PP

- Bag width (min-max):

- 50-190 mm

- Bag length (min-max):

- 50-300 mm

- Max. bag volume:

- 2 Liter

- Max weight per bag:

- 1500 g

- Film thickness PP (min-max):

- 25-80 µm

- Film thickness PE (min-max):

- see AVM 190 HSI

- Film thickness laminates:

- on request

- Max. capacity with PP:

- 100 bags/min

- Max capacity with PE:

- see AVM 190 HSI

- Inner diameter film:

- 75 mm

- Max. diameter film roll:

- 400 mm

- Air pressure:

- 7 bar

- Air consumption:

- 200 -400 l/min

- Machine dimensions (LxWxH):

- 1545 x 928 x 1176 mm

- Machine weight:

- 250 kg

- Voltage:

- 230 V-1ph-50/60Hz

- Consumption:

- 1,4 kW

Specifications HSI

More specifications of the Audion AVM 190 HSI, High speed Impulse for PE film

- Bag width (min-max):

- 50-190 mm

- Bag length (min-max):

- 50-300 mm

- Max. bag volume:

- 2 Liter

- Max. weight per bag:

- 1500 g

- Film thickness PP (min-max):

- See AVM 190 HS

- Film thickness PE (min-max):

- 40-200 µm

- Film thickness laminates:

- on request

- Max. capacity with PP:

- See AVM 190 HS

- Max. capacity with PE:

- 40 bags /min

- Inner diameter film:

- 75 mm

- Max. diameter film roll:

- 400 mm

- Air pressure:

- 7 bar

- Air consumption:

- 300-600 l/min

- Machine dimensions (LxWxH):

- 1545 x 928 x 1176 mm

- Machine weight:

- 250 kg

- Voltage:

- 230 V-1ph-50/60Hz

- Consumption:

- 1,6 kW

Explore our options

Customize the Audion AVM 190 to your needs

Bar coding, printing and labeling

Several solutions are available to have the best possible print or label on your package.

Seal bar configurations

Several seal bar configuration are possible with different type of hole punches (round, euro or carrying handle)

Integratable with dosing systems

A multihead weigher, linear, auger, volume cup dosage or liquid dosage pump the can be integrated.

Form shoulders

Complete range of various form shoulders available to create the ideal bag for your product

Photocell or Window sensor

To automate the start of the bagging process by means of a Photocell (a hand is recognized by the photocell) of by means of a Window Sensor (counting the products which fall into the AVM).

Funnel

Various sizes of funnels are available to faciltate a smooth feed of products into the bag.

Our AVM 190 in use

Let's have a chat

Do you want to know what the Audion AVM 190 can offer for your company? Please feel free to contact us as we are looking forward to exploring together which packing solutions benefit you most.

International Sales

Audion