Produkte

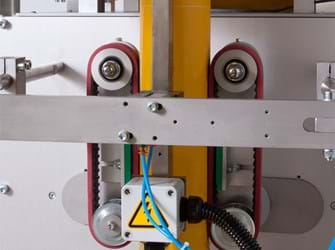

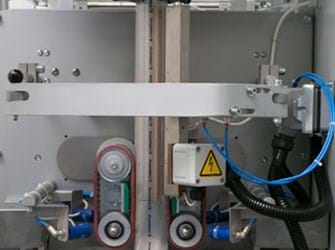

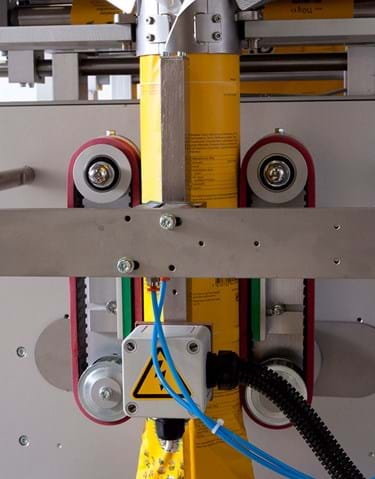

Audion AVM 190

Innovative und kompakteste vertikale Schlauchbeutelmaschine auf dem Markt, die mit hoher Geschwindigkeit arbeitet.

Haben Sie Interesse an Audion AVM 190?

Gerne unterstützen wir Sie bei Ihrer Anfrage oder führen eine Demo mit Ihren Produkten durch.

Bewährte deutsche Qualität seit mehr als 40 Jahren

Audion AVM 190 ist eine kompakte, qualitativ hochwertige vertikale Schlauchbeutelmaschine, die mit einem fortschrittlichen Servo-Antrieb ausgestattet ist und präzise Beutel mit hoher Geschwindigkeit verpackt, um Kosten zu senken und Ihre Geschäftsziele zu erreichen.

Audion AVM 190 wurde entwickelt, um frei fließende Produkte wie Granulate, Pulver, Flüssigkeiten und Feststoffe mit einer Geschwindigkeit von über 100 Beuteln pro Minute zu verpacken.

Die niedrige Maschinenhöhe von 1200 mm ermöglicht einen einfachen Zugang zur Maschine und Flexibilität bei der Produktzuführung (sowohl manuell als auch vollautomatisch). Audion AVM verfügt über ein SPS-gesteuertes Versiegelungssystem für eine optimierte Versiegelung und Hochgeschwindigkeitsabfüllung von Beuteln mit einer Breite von bis zu 190 mm und einer Länge von 300 mm (max. 2 Liter/Beutel). Die Beutelgrößen können einfach über den benutzerfreundlichen Touchscreen eingestellt werden. Über diese Touchscreen-Schnittstelle kann die gesamte integrierte Verpackungslösung gesteuert werden (einschließlich eventueller Schneckenfüller, Förderband und volumetrischer Dosierer).

Audion AVM 190 ist in zwei Versionen erhältlich:

AVM 190 HS: Hochgeschwindigkeits-Heißsiegelgerät für Papier und Folien (Laminate, PP)

- Horizontale und vertikale Heißsiegelung

AVM 190 HSI: Hochgeschwindigkeits-Impulssiegelung für Polyfolien (PE)

- Horizontales Impulssiegeln und vertikales Heißsiegeln

Audion kann die komplette integrierte Verpackungslösung liefern, einschließlich der Dosier- oder Wiege-Einrichtung und der erforderlichen Entladungslösungen.

Durch die Integration der Audion AVM 190 sind Sie versichert von:

- eine robuste und zuverlässige Verpackungslösung

- eine schlüsselfertige Lösung

- Rationalisierung Ihrer Effizienz

- hohe Präzision durch Servo-Antrieb

Dieses macht unsere Maschine einzigartig

Wir arbeiten mit Ihnen zusammen, um qualitativ hochwertige Verpackungsmaschinen anzubieten, damit Sie Ihr Geschäft ausbauen können.

Maßgeschneidert auf Ihre Bedürfnisse

Kein Verpackungsprozess ist wie der andere, das wissen wir bei Audion. Audion AVM hat eine konfigurierbare Konstruktion, so dass die Maschine leicht an Ihre spezifischen Anforderungen angepasst werden kann. Wir bringen fast 80 Jahre Erfahrung mit, um gemeinsam mit Ihnen die am besten geeignete Verpackungslösung zu finden.

Intelligente Maschine - Schlüsselfertige Lösungen

Audion AVM wird oft in eine komplette Verpackungslinie integriert. Wir streben an, die Maschine einfach und schnell in Ihren aktuellen Verpackungsprozess zu implementieren. Wir haben alle Arten von intelligenten Funktionen in das AVM integriert, um dies so einfach wie möglich zu machen. Nicht nur Hardware, sondern auch Software, um die Integration so reibungslos wie möglich zu gestalten.

Ergonomisch & ökologisch geprüft

Das clevere Design der Audion AVM minimiert die Folienüberlappung, um die Folie so effektiv wie möglich zu nutzen. Dies führt zu einer Verringerung des Folienverbrauchs. Der einfache Zugang ermöglicht es Ihnen, Audion AVM einfach und effektiv zu reinigen und zu warten. Sowohl hochvolumige Chargen, Einzelprodukte als auch kleinvolumige Chargen können mit Audion AVM leicht verpackt werden. Die optimierten Reinigungs- und Wartungsfunktionen und der reduzierte Folienverbrauch verschaffen Ihnen große Wettbewerbsvorteile.

Hergestellt in Deutschland

Audion ist ein führender Hersteller von Dichtungsgeräten. Alles begann 1947 an der Seite der berühmten niederländischen Kanäle. Heute verfügen wir über zwei moderne Produktionsstätten in den Niederlanden und in Deutschland, in denen wir Verpackungsmaschinen bauen, die für eine lange Lebensdauer ausgelegt sind. Wir konzentrieren uns auf den Komfort der Endverbraucher und garantieren das beste, sicherste und zuverlässigste Ergebnis.

Videos

Hohe Geschwindigkeit ohne Kompromisse

Geschwindigkeiten von bis zu 100 Beuteln pro Minute und zahlreiche Beuteltypen und -größen sind möglich.

Dies macht die Audion AVM 190 zu einer der universellsten und flexibelsten vertikalen Schlauchbeutelmaschinen auf dem Markt.

Die Konstruktion ist intelligent und kompakt und kann leicht mit einer Wiegeeinheit wie Mehrkopfwaage, Schneckendosierer, Linearwaage oder volumetrischem Becherdosierer integriert werden.

Zusammengefasst:

- Benutzerfreundlicher Touchscreen

- Schnelle Amortisation der Investition

- Reduzierter Folienverbrauch

Vorteile

Audion AVM 190 bietet Ihnen folgende Vorteile:

- Hohe Leistung bei hoher Geschwindigkeit:

- Der leistungsstarke Servo-Antrieb sorgt für eine präzise Absackung bei hoher Geschwindigkeit und maximiert Ihren Output.

- Niedrige Höhe der Maschine:

- Weniger als 1200 mm, d.h. die Produktzufuhr kann manuell oder mit Hilfe eines vollautomatischen Dosiersystems erfolgen.

- Hohe Flexibilität:

- Durch die kompakte Bauhöhe von weniger als 1200 mm kann die Produktzuführung manuell oder über ein vollautomatisches Dosiersystem erfolgen. Darüber hinaus sorgt der integrierte Servo-Antrieb für einen schnellen Folientransport und volle Flexibilität in Bezug auf empfindlichere Materialien und genaue Beutellängen.

- Produktsicherheit:

- Alle Teile, die mit dem Produkt in Berührung kommen, sind aus rostfreiem Stahl gefertigt.

- Leicht integrierbar in die Verpackungslinie:

- Eine breite Palette von Optionen steht zur Verfügung, um Ihre AVM-Einrichtung an die Kommunikation mit Ein- und Auslaufgeräten anzupassen.

- Geringe Stellfläche:

- Kompaktes und robustes Design mit einem Gewicht von nur 250 kg.

- Schnelles Einrichten und geringe Ausfallzeiten:

- Der speziell entwickelte Folienrollenhalter ermöglicht ein schnelles und einfaches Einlegen der Folie und sorgt so für einen minimalen Verlust an Produktionszeit.

- Langlebigkeit:

- Audion verwendet hochwertige Komponenten und industrielle Materialien, die für eine lange Lebensdauer Ihrer Maschine stehen.

- Hohe Vielseitigkeit:

- Audion AVM kann eine Vielzahl von Produkten verpacken, wie z.B. Pulver, Granulat und Teile in verschiedenen Formen und Arten, wie z.B. Süßigkeiten, Kaffeebohnen und Snacks usw.

- Einfache Wartung:

- Audion AVM ist so konstruiert und gebaut, dass er leicht zu reinigen und zu warten ist. Formsatz und Verschleißteile wie Messer können leicht ausgetauscht werden, um die Ausfallzeiten zu minimieren.

- Automatische Backenentriegelung:

- Wenn ein Produkt zwischen den Schweißbalken eingeklemmt ist, werden die Schweißbalken automatisch freigegeben.

- Benutzerfreundliches Bedienfeld:

- Der Betrieb kann über ein integriertes Bedienfeld gesteuert werden, das die Speicherung von Aufträgen, Chargenzählern, Statistiken, Log-in-Ebenen und bis zu 50 Rezepten ermöglicht.

- Schnelle Problemlösung:

- Das Selbstdiagnose-Informationssystem gewährleistet eine schnelle Problemlösung und minimale Ausfallzeiten.

- Mobilität:

- Die montierten Laufrollen ermöglichen eine optimale Mobilität.

- Siegelung mit Klappe möglich:

- Audion AVM ermöglicht die Herstellung einer Siegelung mit Klappe. Ideal für Folienmaterialien, die nicht versiegelt werden können (dieses Material sollte mit einer Beschichtung versehen sein, die innen versiegelt werden kann).

- Fotozelle für vorbedruckte Folie:

- Im AVM-Standard ist eine Fotozelle für vorbedruckte Folie integriert.

- Hygienische Ausführung:

- Schnell und einfach zu reinigen

Optionen

Die nachfolgenden Optionen stehen für Audion AVM 190 zur Verfügung:

- Zwei Ausführungen:

- High Speed für Laminate und PP (HS) und High Speed Impulse für PE-Folie (HSI).

- Gasspülung:

- Das Einblasen eines Gases vor der Versiegelungsphase erhöht die Haltbarkeit des Produkts, bietet zusätzlichen Schutz und verhindert die Verfärbung des Produkts.

- Unterstützungstisch:

- Erforderlich für Beutel mit einem Gewicht von mehr als 1,5 kg.

- Staubabsaugung:

- Verhindert das Eindringen von Staub zwischen die Schweißbalken, ratsam bei staubigen Produkten wie Pulver.

- Produktauffangplatten:

- Brechen den Fall der Produkte und schützen auf diese Weise das Produkt und den Beutel.

- Zentrale Bahnverfolgung:

- Hält die Folie automatisch in der Mitte des Formatsatzes.

- Luftpressvorrichtung:

- Entfernt die Luft aus dem Beutel, montiert oberhalb des Schweißbalkens.

- Doppel-Schlag inklusiv aufgeständertes Maschinengestell:

- Um einen längeren Beutel zu schaffen.

- Doppelsiegelung:

- Zum Verpacken von flüssigen Produkten.

- Löcher:

- Rund, Euro oder Tragegriff.

- Quatro-Dichtung:

- Produziert Standbodenbeutel mit quadratischem Boden und vier gesiegelten Seiten. Geeignet für die Verpackung einer Reihe von Granulat-Produkten, insbesondere für Produkte, die einen hohen Verpackungsstandard ohne Faltenbildung erfordern.

- Fotozell oder Fenstersensor:

- Gibt dem Audion AVM ein Startsignal zur Aktivierung.

- Produkt-Rüttler:

- Zum Verteilen des Produkts im Beutel.

- Motorisch angetriebene Folienspule:

- Zusätzliche Unterstützung für das Beschleunigen und Abbremsen von schwereren Folienrollen.

- Vorrichtung zur Vermeidung von Anhaften:

- Verhindert das Anhaften von Beuteln am Schweißbalk.

- Statische Beseitiger:

- Verhindert, dass Staub an der Folie haften bleibt, ratsam bei der Verpackung staubiger Produkte wie Pulver.

- Fußpedal:

- Empfehlenswert für den manuellen Betrieb.

- Verschiedene Formatsätze verfügbar:

- Audion bietet verschiedene Formatsätze zur Herstellung unterschiedlicher Beutel an.

- Verschiedene Codierungsmöglichkeiten:

- Ein Thermodrucker oder Etikettierer ist verfügbar, um Ihre Beutel mit einem klaren Aufdruck zu versehen.

- Dosiersysteme:

- Zur Optimierung Ihrer Produktzufuhr mit Audion AVM 190 HS(I) steht eine breite Palette von automatischen Dosiersystemen zur Verfügung. Mehrkopfwaagen, verschiedene Schnecken- oder Pumpensysteme, je nach den Eigenschaften Ihrer Produkte.

Verpackungsarten

Die folgenden Beuteltypen können mit Audion AVM 190 hergestellt werden:

- Kissenbeutel:

- Wie der Name des Beutels schon sagt, hat er die Form eines Kissens. Sobald er gefüllt ist, bläht er sich in der Mitte auf und wird an den oberen und unteren Verschlüssen flach. Kissenbeutel werden am häufigsten für Einzelportionsprodukte verwendet.

- Blockbodenbeutel:

- Blockbodenbeutel zeichnen sich durch einen rechteckigen, flachen Boden und einen Einschlag an den Seiten aus.

- Seitenfaltenbeutel:

- Der Boden eines Seitenfaltenbeutels ist flach. Die flache Oberfläche des Beutels ermöglicht es den Beuteln, ohne äußere Unterstützung zu stehen. Die Seitenfalten sind so gestaltet, dass der größte Teil des Produkts, wenn der Beutel mit einem Produkt gefüllt ist, auf den Boden des Beutels sinkt - in die Nähe der Seitenfalte.

- Kettenbeutel:

- Beutel, die versiegelt, aber noch miteinander verbunden sind

Spezifikationen HS

Weitere Spezifikationen für Audion AVM 190 HS, High speed für Laminate und PP:

- Beutelbreite (min-max):

- 50-190 mm

- Beutellänge (min-max):

- 50-300 mm

- Max. Beutelvolumen:

- 2 Liter

- Max Gewicht pro Beutel:

- 1500 g

- Folien-Dicke PP (min-max):

- 25-80 µm

- Folien-Dicke PE (min-max):

- Siehe AVM 190 HSI

- Folien-Dicke von Laminaten:

- auf Anfrage

- Max. Kapazität mit PP:

- 100 Beutel/min

- Max. Kapazität mit PE:

- Siehe AVM 190 HSI

- Innen Durchmesser von Folie:

- 75 mm

- Max. Durchmesser Folienrolle:

- 400 mm

- Luftdruck:

- 7 bar

- Luftverbrauch:

- 200 -400 l/min

- Maschine-Abmessungen (LxBxH):

- 1545 x 928 x 1176 mm

- Maschine-Gewicht:

- 250 Kg

- Spannung:

- 3 x 230V/400V-N-PE 50-60Hz

- Verbrauch:

- 1,4 kW

Spezifikationen HSI

Weitere Spezifikationen für Audion AVM 190 HSI, High speed Impulse für PE Folie:

- Beutelbreite (min-max):

- 50-190 mm

- Beutellänge (min-max):

- 50-300 mm

- Max. Beutelvolumen:

- 2 Liter

- Max. Gewicht pro Beutel:

- 1500 g

- Folien-Dicke PP (min-max):

- Siehe AVM 190 HS

- Folien-Dicke PE (min-max):

- 40-200 µm

- Foliendicke von Laminaten:

- auf Anfrage

- Max. Kapazität mit PP:

- Siehe AVM 190 HS

- Max. Kapazität mit PE:

- 40 Beutel /min

- Innen Durchmesser von Folie:

- 75 mm

- Max. Durchmesser Folienrolle:

- 400 mm

- Luftdruck:

- 7 bar

- Luftverbrauch:

- 300-600 l/min

- Maschine-Abmessungen (LxBxH):

- 1545 x 928 x 1176 mm

- Maschine-Gewicht:

- 250 Kg

- Spannung:

- 3 x 230V/400V-N-PE 50-60Hz

- Verbrauch:

- 1,6 kW

Entdecken Sie unsere Optionen

Konfigurieren Sie Audion AVM 190 für Ihre Ansprüche:

Barcodierung, Druck und Etikettierung

Es stehen mehrere Lösungen zur Verfügung, um Ihre Verpackung optimal zu bedrucken oder zu etikettieren.

Schweißbalken-Konfigurationen

Verschiedene Schweißbalken-Konfigurationen sind möglich mit verschiedenen Arten von Lochstanzen (rund, Euro oder Tragegriff).

Integrierbar mit Dosiersystemen

Eine Mehrkopfwaage, eine Linearwaage, eine Schnecke, eine Volumenbecherdosierung oder eine Flüssigdosierpumpe können integriert werden.

Formatsatz

Komplettes Sortiment an verschiedenen Formsätzen verfügbar, um den idealen Beutel für Ihr Produkt zu schaffen.

Fotozelle oder Fenster-Sensor

Zur Automatisierung des Starts des Absackvorgangs mittels einer Fotozelle (eine Hand wird von der Fotozelle erkannt) oder mittels eines Fenstersensors (Zählen der Produkte, die in das Audion AVM fallen).

Trichter

Verschiedene Trichtergrößen sind erhältlich, um eine reibungslose Zuführung der Produkte in den Beutel zu ermöglichen.

Sprechen Sie uns an

Sie wollen wissen, was Audion AVM 190 für Ihr Unternehmen bieten kann? Bitte zögern Sie nicht, uns zu kontaktieren, wir freuen uns darauf, gemeinsam herauszufinden, welche Verpackungslösung Ihnen am meisten zugute kommt.

Vertrieb Deutschland

Audion