Audion - Alain Caron

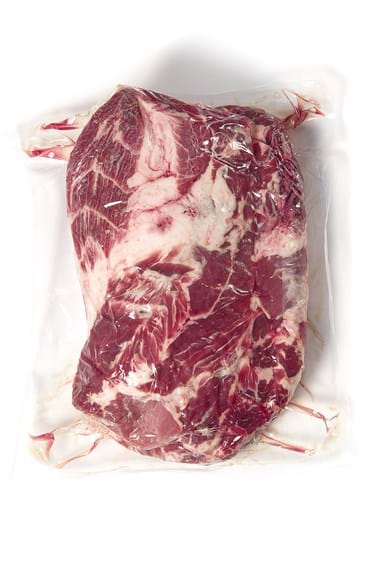

Audionvac vacuum packaging machine used by Famous Dutch chef, Alain Caron.

Choose a country to view content specific to your geographical location

Products

Most popular table top vacuum chamber machine with a powerful 21 m3/h pump, fully customizable

We are more than willing to support you with your request or run a demo with your packaging

This vacuum chamber machine belongs to the most popular table top vacuum chambers in the world and that is not without a reason. Made exclusively with high-quality individual components, equipped with high performance pump and smart digital control panel with clear recipe structure. These are just a couple of examples why the Audionvac VMS 153 profits from this reputation.

The wide selection of options allows you to optimize the vacuum process to your product's characteristics, whether it concerns liquid products, fragile products or voluminous hard products.

You tell us your desired product care and we customize the VMS 153 up to the max!

To sum up:

We work together with you in providing the best quality packaging machines to help you grow your business

The digital control panel with 10 program memory permits the precise setting of vacuum, gas (optional), seal times and guarantees the reproducibility. The soft air option allows you to reduce the oxygen level in a controlled manner: the air is gradually and gently returned into the chamber. In this way the vacuum bag envelopes the product in a controlled way, realizing optimal protection of both the product and the vacuum bag.

Synergy of contact pressure, seal temperature and seal time produces optimum fusing results.The Audionvac makes sure the values of the above mentioned variables are in perfect balance – to create the perfect seal and perfect package.

In today’s world, everyone relies on their products. It is crucial that equipment functions with highly efficient performance. When they fail to do so, it can lead to the customer being exasperated. Therefore Audion offers a warranty period of 3 years on the Audionvac VMS 153. Spare parts are easy and widely available. This guarantees a safe and reliable function of your product for now and for the future.

During the design of Audionvac VMS 153 we placed our users at the centre. This resulted into a professional vacuum machine, industrial grade, with ease of installation and operation. Operators don’t need an extended training as the machine and the way the software is being built up speaks for itself – plug and play. Noise level and energy consumption of the Audionvac VMS 153 are reduced to a level hard to beat, all being in favour of the end-user.

The Audionvac VMS 153 is made from heavy industrial materials which gives it a strong and professional look and feel.

Standard richly equipped with:

The Audionvac VMS 153 gives you the following benefits

The following options are available on the Audionvac VMS 153

Discover the available spare parts for your VMS 153. Audion original quality.

More specifications of the Audionvac VMS 153

Customize your Audionvac VMS 153 to your product's needs

Cut-off seal, to easily tear off the residual film for optimized hygiene. 1-2 Cut off seal, same as cut-off seal but in addition with 1-2 cut-off seal the time and settings of the seal and cutting wire can be managed separately.

8 mm wide seal for an aesthetic and professional result.

Injecting a gas before the sealing phase increases the product's shelf life, it offers extra protection and it prevents the product from colouring.

Vacuum packaging machines equipped with Sensor control calculate when the pre-set percentage has been achieved. This guarantees a constant end vacuum of your package. Always. Especially recommended when packing various types of products with different volume.

Convenient for packing liquids and powders, such as soups and flour. The inclined insert plate accomodates that products are placed in an angled position, facilitating that the product stays at its place.

Do you want to know what the Audionvac VMS 153 can offer for your company? Please feel free to contact us as we are looking forward to exploring together which packing solutions benefit you most

International Sales

Audion

Sales United Kingdom

Audion

Please fill in the below form and we will respond to you as soon as possible.