Audion Calibration, Verification, and Validation Services

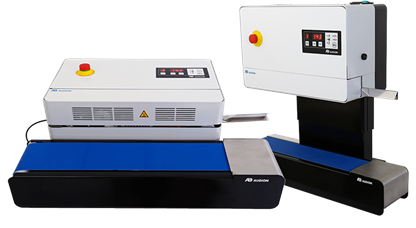

Audion offers comprehensive calibration services for our extensive range of validatable sealers, widely used in the Medical, Pharmaceutical, and High-Tech industries. All our validatable sealers, rotary heat sealers, validatable Speedpack machines, and validatable vacuum chambers can benefit from our services. Regular user verification and annual re-calibration ensure that our sealers consistently deliver the required seal quality.

The quality and consistency of the seal are determined by three key parameters: temperature, time/speed, and pressure/force. For vacuum chambers, vacuum pressure is also a critical factor.

During calibration, our service engineers meticulously calibrate and adjust these parameters as needed, providing you with a traceable calibration certificate issued in accordance with an ISO 9001 quality management system.

Our reference standards are calibrated under ISO 17025 accreditation, ensuring traceability to national and international standards.

We offer three distinct services for the calibration and validation of our packaging machines:

-

Audion Factory Calibration: Ensures precise sealing parameters of the packaging machine, marking the first step towards ISO 11607-2:2019 compliance.

-

IQ/OQ Check (Installation/Operational Qualification): Verifies that the machine and materials consistently produce the required seal. Audion provides essential documentation for your validation process.

-

Seal Integrity Tests: Our technician will use calibrated instruments and test kits to conduct thorough inspections. A detailed certificate, including all relevant documentation, will be provided upon completion. For regular seal inspection, we offer a comprehensive range of tools and accessories tailored to your specific needs.