Products

MEDSEAL® - MSIDV

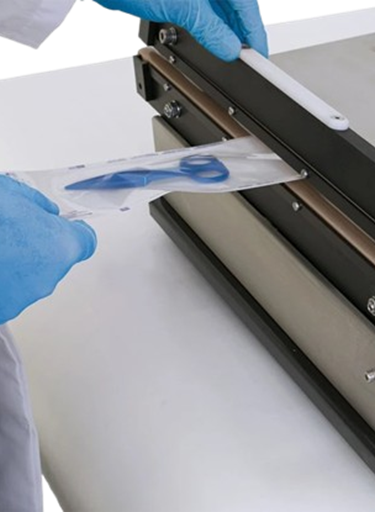

Validatable electric impulse sealer for medical grade packaging

Interested in our MEDSEAL® - MSIDV?

We are more than willing to support you with your request or run a demo with your packaging

New MSIDV – High Integrity Medical Sealer

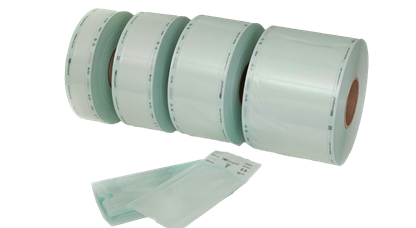

The newly developed Audion MEDSEAL® MSIDV represents a significant upgrade from the previous generation, now equipped with the advanced Audion Temperature Controller (ATC) for more precise and consistent temperature control. Combined with the intuitive Audion LCD Key-panel (ALK), the MSIDV ensures a user-friendly, reliable and fully validatable sealing process for medical and healthcare products. Its electrically driven bi-active seal bars deliver powerful sealing pressure, creating strong and uniform 8 mm seals across a wide range of medical packaging materials, including Polypropylene, Polyethylene, and Paper-PP.

An optional integrated knife and film roll holder trims excess film above the seal for optimal hygiene, reducing packaging volume, and enabling the use of tubular film.

This validatable and electrically driven impulse sealer fully complies with EN868-5 (section 4.3.2), DIN 58953 part 7, and ISO 11607-2 standards, making it ideal for applications requiring high seal integrity and traceability. This new MSIDV also offers datalogging via USB.

The stainless steel covering is easy to clean, highly durable, and perfectly suited for demanding medical environments.

Key Features:

-

Validatable impulse sealer for medical packaging

-

Seal lengths: 460 mm (MSIDV 462), 610 mm (MSIDV 612)

-

Electrically driven, no air pressure needed

-

Complies with EN868-5, DIN 58953-7, ISO 11607-2

-

Durable, easy-to-clean stainless steel design

-

Audion LCD Key Panel (ALK): Clear, intuitive display.

-

Audion Temperature Controller (ATC): Precise temperature control

-

Alarm function for seal temperature/force deviations.

-

Stores 10 recipes for quick setup.

Please note: The Audion MEDSEAL® MSIDV with ATC and ALK will be available from mid September. Contact us for more information.

This makes our machine unique

We work together with you in providing the best quality packaging machines to help you grow your business

Precise Temperature Control

The new MSIDV sealer is equipped with the advanced Audion Temperature Controller (ATC), ensuring highly accurate seal temperature control for a more precise sealing and validation process compared to the previous 460/611 series. Calibration is user-friendly thanks to the standard integrated analog port.

Plug and play

The MSIDV is constructed with integrated electromagnets, which means no need of external air pressure and easy implementation of this medical sealer into your production.

Guaranteed safe packaging

The validation feature ensures that critical process variables are controlled guaranteeing a safely packed product after each finished sealing cycle. In case of an error or deviation the seal cycle is stopped and an alarm will notify you.

Smart data logging & Secure seal settings

The new MSIDV series features a USB port for easy data logging. Up to 10 seal recipes can be stored in the ALK controller, enabling quick and accurate parameter selection for each product. To ensure optimal protection of settings, the sealer includes 3 user levels, providing controlled access and safeguarding your validated sealing process.

Validation of the process variables

The Audion MEDSEAL® is a validatable medical impulse sealer that requires verification of all seal process variables at regular basis. Audion offers a wide range of verification instruments that enable you to verify the critical seal parameters.

- Available verification instruments include:

- ATM (Audion Temperature Meter) measures and verifies the sealing temperature

- AFMR (Audion Force Measurement Ring) measures and verifies the sealing pressure

- Seal Integrity Test (SIT): a service which includes seal check, dye penetration test and peel test

- Calibration: a service (incl. Calibration Certificate) that certifies the preciseness of the sealing parameters of your packaging machine

- Validation documents:

- Installation Qualification (IQ) ensures that the machine is in good condition and functionality, and is calibrated

- Operational Qualification (OQ) optimizes the machine to create quality seals with customers' packaging materials

Benefits

The Audion MEDSEAL® gives you as an end-user the following benefits

- Controlled seal parameters:

- Seal temperature, seal time and seal pressure are fully controlled.

- Easy to install:

- No external air needed due to integrated electromagnets performing a strong seal pressure.

- Monitoring:

- Alarm when seal temperature / seal force are beyond set tolerance.

- User-convenience:

- Easy-to-use LCD control panel (10 recipes).

- Precise Temperature Control:

- The Audion Temperature Controller (ATC) ensures precise temperature control, vital for achieving optimal seal integrity and maintaining compliance.

- Traceability:

- Data logging via USB

- Heavy duty design:

- Stainless steel design and strong 8 mm seal.

- Easy-to-clean:

- Durable stainless steel covering (AISI 304).

Options

The following options are available on the MEDSEAL®

- Verification equipment:

- Audion offers various devices to verify the temperature (ATM) and seal pressure (AFMR) of your seal.

- Tubular film configuration:

- Cutting device (cutting length max. 370mm/500 mm) and film roll holder.

- Foot operation:

- Facilitating both hands free to hold/guide the package.

- Work table:

- Stainless steel work table suitable for both the 460 and 610 mm model.

- Alternative voltage:

- 115V version.

- Calibration:

- Calibration executed by Audion's service dept. (Audion recommends re-calibration every year).

- IQ/OQ:

- Includes max 2 days work on site - travelling excluded.

Spare parts

Discover the available Audion original quality spare parts for your Medseal® (MSIDV).

- Spare parts

- ← Click to select the required spare parts for your Medseal®

Specifications

More specifications of the Audion MEDSEAL - MSIDV

- Type of machine:

- Validatable medical impulse sealer

- Models:

- 462 MSIDV | 612 MSIDV

- Machine dimensions WxDxH

- 462 MSIDV: 560 x 360 x 235 mm / 612 MSIDV: 710 x 360 x 235 mm

- Type of seal:

- Bi-active seal, flat seal

- Seal width:

- 8 mm

- Seal length:

- 460 or 610 mm

- Film thickness:

- Min. 2x20 micron / Max. 2x200 micron

- Control system:

- Audion Temperature Controller (ATC) + Audion LCD Keypanel (ALK)

- Seal temperature setting range:

- 100 – 200 °C

- Temperature tolerance range:

- 0 – 20 °C (default 5 °C)

- Cooling temperature setting range:

- 50 – 150 °C

- Temperature accuracy:

- +/- 3°C or +/- 2% (whichever is larger)

- Seal time setting range:

- 0.8 – 10.0 sec.

- Login levels:

- Operator, Supervisor (password access) and Administrator (password access)

- Covering:

- Stainless steel (AISI 304)

- Knife + film roll holder:

- Yes, optional

- Type of film:

- PP (Polypropylene), PE (Polyethylene), Paper-PP, Medical Pouches

- Power supply:

- 230 V – 1ph – 50/60Hz

Explore our options

Customize your MSIDV to your needs

Convenient worktable

A convenient support table for your products, applicable for both 462 MSIDV and 612 MSIDV

Cutting device

Removes the residual film above the seal. Can be used to create custom bags from tubular film or for ready-made bags.

Calibration

Calibration executed by Audion's service department with validated equipment

IQ/OQ

Installation- and operational quality test on site to ensure the sealing performance

Related products

Let's have a chat!

Do you want to know what the MEDSEAL® - Medical Impulse Sealer can offer for your company? Please feel free to contact us as we are looking forward to exploring together which packing solutions benefit you most.

International Sales

Audion