Spare parts set for Power Sealer

520|720|1020|1320 IST/MV (TC)(MED)(PLUS)(IP65)(SILA)

Choose a country to view content specific to your geographical location

Products

Fully temperature controlled robust impulse sealer for reliable packaging of food and high-tec products

We are more than willing to support you with your request or run a demo with your packaging

This high-performance and fully temperature controlled Power Sealer has been designed following the critical packaging needs in High-tec and Food industry where temperature controlled sealing and process alarm on seal temperature is required.

The advanced Audion Temperature Controller repeatedly ensures precise temperature regulated seal cycles for reliable packaging of delicate products like electronic devices or food products, such as powders or spices, granulates or large pieces of meat. An alarm function (with adjustable tolerances) is available to stop the cycle in case of unexpected deviation in seal temperature.

The robust heavy duty stainless steel housing is easy-to-clean and equipped with the renowned Audion Touch Techware for easy monitoring the critical control parameters. It enables the pre-setting of 50 parameter recipes, precise control of seal temperature and seal time. Batch and cycle information can be stored and downloaded.

Powerful bi-active and pneumatic sealbars effectively produce a consistent 8 mm seal in film, laminates and other thick materials, even during intensive use.

Features like Vacuum and Modified Atmosphere Packaging (gas flush), integrated cleaning system and a powder filter are optionally available.

Audion designed a wide range of options to customize your Power Sealer TC to your product.

Your Power Sealer TC advantages:

We work together with you in providing the best quality packaging machines to help you grow your business

Sealing & cooling temperature, sealing time and eventual vacuum & gas cycles are controlled, ensuring a consistent seal quality, even during intensive sealing. An alarm can be set on eventual deviation in seal temperature. Sealing temperature can be officially calibrated by applying Audion Factory Calibration (optional).

The user-friendly Audion Touch Techware integrates the advanced Audion Temperature Controller and a clear HMI touchscreen for pre-setting 50 recipes and precise monitoring of the seal temperature. Batch and cycle information can be stored and downloaded.

Configurable with integrated vacuum and gas flush system enabling MAP (Modified Atmosphere Packaging) to mimimize the volume of package and to optimize the shelf life of food.

A wide range of special options for high-tech and food applications have been designed to optimize the quality of your product during packaging.

All Power Sealers can be configured for ‘sealing only’ or with an integrated vacuum system.

Audion's Vacuum Power Sealers are equipped with a venturi pump generating a powerful vacuum, ideal for operating in a continuous packaging process, reducing production time. The venturi pump is virtually maintenance free (operating without oil). The vacuum system can be combined with gas flush to create modified atmosphere packaging (MAP).

An integrated vacuum system can be used for:

The Power Sealer TC gives you the following benefits

The following options are available on the Power Sealer TC

The following accessories are available to customize your Power Sealer TC to product and production environment

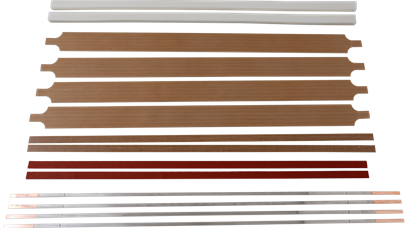

Almost all Audion machine parts are readily available from stock, ensuring timely replacements and maintaining high seal quality during your packaging processes.

More specifications of the Power Sealer TC

Customize your Power Sealer TC to your unique requirements

To adjust your sealer to the ideal sealing height and sealing angle and maximize ergonomic advantages. Various support options are available, such as bag support or roller conveyor. All to create the ideal packaging solution for your product and operator.

Audion has designed several options to optimize your food packaging process. A powder filter, liquid separator, quick cleaning system for powders, particle ejection system (to clear the vacuum tubing after every vacuum cycle) are all available to customize your Power Sealer TC and ultimately protect your product.

Especially designed (cleanroom) solutions are available to guarantee the safety and quality of your products, such as exhaust options, electrostatic discharge function or silicone poor machine design.

Bagstretchers can be mounted to tighten the bag neatly alongside the seal bar. In this way it will be easier to provide wrinkle-free seals while keeping the bag properly tensioned.

This no-nonsense Power Sealer forms the solid basis of the renowned Power Sealer line. The outstanding 5 mm sealing performance is achieved by a pneumatic bi-active and time-controlled impulse sealing system. Standard vacuum feature integrated.

This model is validatable and generates an 8 mm temperature- and time controlled seal. The validation enables that critical seal variables like seal force, seal temperature and seal time are being controlled.

The Power Sealer TC is a high-performance temperature controlled sealing machine designed for demanding packaging needs in the high-tech and food industries. It features a durable stainless steel housing, touchscreen interface, and powerful bi-active and pneumatic seal bars that ensure consistent, airtight seals.

The next step in the Power Sealer line is the Plus version. With its unique and most precise system of validation it meets todays' most stringent packaging requirements. 8 mm Temperature- , time- and force controlled seal. Includes Audion Touch Techware.

Our flagship model in the Power Sealer line. Especially designed for dusty, humid or regulated (clean room) production environments. Highly advanced validatable impulse sealer. An 8 mm temperature-, time and force controlled seal. Includes Audion Touch Techware. Also available in Bag-in-box configuration.

The Power Sealer TX CL and Power Sealer PLUS XL have the largest sealing length of the Audion Power Sealer range. With a sealing length of 2500 mm they can effortlessly provide your largest products with customized packaging or protective covers by means of an 8 mm seal. Available in a temperature controlled model (PSR TC XL) and a validatable model (PSR PLUS XL) with validation on temperature-, time- and seal force controlled sealing.

Unique steamsealer enabling bags to be sealed without electrical power supply. Instead, it uses pressurized steam to operate. suitable for explosive environments. 8 mm temperature controlled seal.

Do you want to know what the Audion Power Sealer TC can offer for your company? Please feel free to contact us as we are looking forward to exploring together which packing solutions benefit you most.

International Sales

Audion

Sales United Kingdom

Audion

Please fill in the below form and we will respond to you as soon as possible.