Products

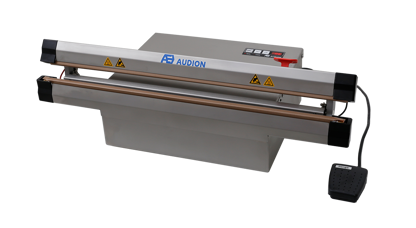

Power Sealer PLUS IP65

World-leading seal integrity, highly precised validatation control and fully IP65

Interested in the Audion Power Sealer PLUS IP65?

We are more than willing to support you with your request or run a demo with your packaging

Uncompromised packaging for highly-demanding environments

The PSR PLUS IP65 is the star performer within the renowned Power Sealer line and ensures unparalleled product safety and quality in highly regulated settings. This validatable impulse sealer combines high-class seal performance of the PLUS series with the guarantee of dust- and humidity-proof protection.

Features like external air exhaust, to avoid contamination of your production area or cleanroom environment are standard included, all to ensure your product being packed at most secure requirements.

The high-end Audion Touch Techware comes standard in the PLUS, guaranteeing an optimized packaging control and product quality. Consistent quality seals are ensured by the Audion Temperature Controller, even during intensive use. Alarms on critical seal parameters like seal temperature, seal time, seal force and vacuum/gas time (vacuum models) can easily be set with configurable tolerance. Batch and cycle information can be stored and downloaded.

Audion's PLUS IP65 offers you high-class sealing technology which brings peace of mind in demanding environments like food or powder packaging in pharmaceutical and chemical industries.

When vacuum or MAP packaging is desired, the VAC PSR PLUS IP65 are the go-to choice: standard equipped with a powerful vacuum /gas flush system with double nozzles.

Your Power Sealer PLUS IP65 benefits:

- Suitable for operation in dusty and humid work environments

- Integrated Audion Temperature Control to ensure consistent seals

- Ultimate control of all critical seal parameters, most precise validation measurement

- Possibility to store 50 pre-set seal parameter settings for different products/film types

- All our PLUS series impulse sealers are compatible with EN 868-5 and DIN 58953, part 7 norms. Our PLUS series impulse sealers also fully comply with the ISO 11607-2 and ISO/TS 16775

- Standard configured for high-demanding industries with high-standard packaging requirements.

This makes your machine unique

We work together with you in providing the best quality packaging machines to help you grow your business

Richly equipped as standard

Features like the robust stainless steel housing, solidly mounted bi-active sealing bars, Audion Touch Techware and external air exhaust make this industrial sealer the most-advanced tech magic in its class, reaching the highest degree in validation and often applied for cleanroom packaging.

Uniquely embedded technologies

In-house designed hardware and software features work together to optimize your productivity and meet the highest standards in seal technology. The Audion Temperature Controller ensures that every seal is made at the same temperature, ensuring a consistent and hermetic quality seal, even during intensive use.

Guaranteed ultimate seal integrity

Sealing temperature, sealing time and seal force can be controlled, monitored and recorded ensuring a 100% reliability of each seal.

Suitable for use in demanding work areas

Ultimate product safety and quality thanks to the dust- and splash proof, easy-to-clean IP65 design. Preventing internal and external contamination.

Videos

An integrated vacuum and/or gas flush system

The Power Sealer PLUS IP65 can be configured for ‘sealing only’ or with an integrated vacuum system.

Audion's Vacuum Power Sealers PLUS IP65 are equipped with a venturi pump enabling a powerful vacuum result, ideal for operating in a continuous packaging process, optimizing production time. The venturi pump is virtually maintenance free (operating without oil).

The vacuum system can be combined with gas flush to create modified atmosphere packaging (MAP). The gas flush system ensures safe and quality-controlled packaging of all kinds of products and extends the shelf life of food products, can provide sterile protection essential for medical instruments and minimizes the change of metals oxidizing of e.g. electric equipment and delicate components.

The VAC PSR PLUS IP65 is standard fitted with many cutting edge vacuum features and exhaust preparations, which is why they are ideal for use in a wide range of applications including cleanroom environments.

The integrated vacuum system can be used for:

- Volume reduction of the package to save storage and shipment costs

- Applying a modified atmosphere (MAP) to extend the shelf-life of food products

- Prevention of oxidation of, for example, printed circuit boards or other delicate products.

Benefits

The Audion PSR PLUS IP65 gives you the following benefits

- IP65 heavy-duty design:

- The IP65 dust and splash resistant construction protects the product against the risk of contamination. Designed for demanding environments like food industry and chemicals where hygiene and safety during operation are essential.

- Consistent seal quality

- Audion Temperature Control system integrated, ensuring consistent seals even during intensive operation.

- Advanced control and monitoring:

- The standard built-in Audion Touch Techware includes the validatable Audion temperature controller and runs on in-house designed software allowing you to fully control and monitor the critical seal parameters. The user-friendly HMI touch screen allows you to run your packaging process efficiently and effortlessly.

- Protected seal cycle:

- No errors can be tolerated. Therefore an integrated 3 level log-in (operator, supervisor and administrator protected seal cycles) comes standard in the Power Sealer PLUS IP65.

- Data transfer:

- The USB port enables you to download batch information of critical seal-parameters

- Ingenious technology:

- You are assured of the highest seal integrity and efficiency thanks to standard functionalities such as pre-programmable seal recipes and operation height recipes. This will cause the Power Sealer to adjust to the ideal settings fully automatically.

- Safe & convenient handling:

- The well-equipped packaging solution is standard equipped with several features that guarantee the safety of yourself and your product. Furthermore, this configurable solution offers the possibility to accommodate specific requirements to support a smooth packaging process that guarantees product and operator safety.

- External air exhaust system:

- Standard included, the external air exhaust system prevents contamination of your production area or cleanroom environment by efficiently removing residual air and particles, ensuring a cleaner and safer workspace while maintaining the integrity of your packaged products.

Options

The following options are available on the Audion PSR PLUS IP65

- Vacuum and gasflush system:

- Integrated vacuum/gasflush system with various nozzle, powder/liquid filter, pumps (Venturi 11 m³ / 20 m³ or side channel pump 85 m³ (Busch)) and exhaust options.

- Automatic height adjustment during the vacuum process:

- Provides better seal and vacuuming results when packing large bags. The machine automatically descends during the vacuum process, preventing tension on the bag and allowing vacuuming closer to the product.

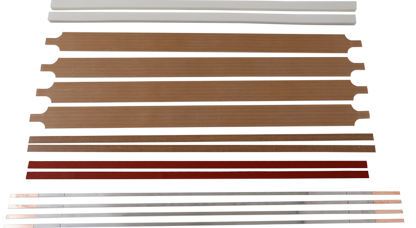

- Configurable seal bars:

- Various seal bar configurations like 5 mm seal, 10 mm seal and silver plated sealwire etc. to make the best fit to your product/film type.

- Bag stretchers:

- Bag stretchers ensure that the bag is stretched, to prevent folds in the seal.

- Cleanroom solutions:

- Various clean room solutions available to optimize a safe and clean packed product e.g. silicone poor machine, ESD, external exhaust options etc.

- External control box:

- Provides the ability to control the machine externally (e.g., for use of the PSR PLUS IP65 in a cross-flow cabinet).

- Hygiene & visual presentation solutions:

- Cutting device, partical ejection system and quick cleaning system for powder filter etc.

- Big bag/Bag-in-box:

- Especially designed for sealing and vacuuming (large) bags in a box or barrel. Includes automatic lift down of the vacuum nozzle into the bag, nearest to the product.

- Heavy Venturi pump:

- When using larger bags, a more powerful pump will improve the vacuum capacity. When mounting the larger pump, the piping, valve and hosing in the machine will also be adjusted.

- External Venturi Pump:

- Mounted on support frame or attached to machine body (backside). Prevents contamination of the interior of the machine and allows easy access for cleaning purposes.

- High capacity side channel Busch pump:

- Provides a high suction capacity (85 m³/h) ideal for extra large bags and/or vacuum packaging powders. Powerful and fast vacuuming of a big air volumes in a short time span and a low vacuum level end result. Optional ATEX-certified version available.

- User level Administration:

- User level registration, access rights and user registration can be protected by passwords to keep full control over the seal integrity of your packing processes.

- Calibration service:

- Audion provides calibration services for our validatable sealers. The critical process parameters (seal temperature, seal force, seal time/speed, etc.) are measured with traceable measuring devices and a calibration certificate will be issued.

- Installation and operative quality check:

- Audion offers certified IQ/OQ checks, operation and maintenance training to get the most out of your Validatable Power Sealer.

- Extra thick film configuration:

- A thick film configuration when intensively sealing films of > 150my, or more film layers.

- Water cooled sealing bars:

- Faster cooling of the seal bars which shortens the seal cycle for a higher production quantity and improved seal quality.

- Power supply adjustment:

- Machine configured for 115V grid current.

Accessories

The following accessories are available on the Power Sealer PLUS

- Manual Industrial Frame:

- This robust industrial frame is designed for easy manual operation. The sealing height can be adjusted manually to meet your specific requirements. Ideal for industrial applications where precision and durability are essential. Various extra (product support) options are available.

- Motorized Support Frame:

- Our advanced motorized frame comes equipped with electric drive. It allows you to easily set the sealing height via the sealer’s recipe. This frame is ideal for production lines where speed, consistency, and automation are crucial. Various extra (product support) options are available.

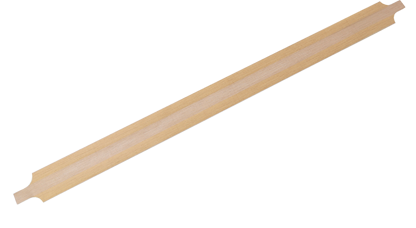

- Set of wearing parts:

- Convenient set for quickly replacing the PTFE, rubber and seal wire to do easy maintenance. To guarantee an optimal sealing result, also after regular use.

Spare parts

Almost all Audion machine parts are readily available from stock, ensuring timely replacements and maintaining high seal quality during your packaging processes.

- Webshop

- Visit our webshop to explore the range of Audion original quality wearing parts.

Specifications

More specifications of the Audion Power Sealer PLUS IP65

- Seal length:

- 720, 1020 mm

- Seal width:

- 8 mm

- Film thickness:

- 2 x 20 micron - 2 x 300 micron

- Type of seal:

- Temperature-, time- and force controlled impulse seal

- Operation:

- Digital control panel, Audion Touch Techware, touchscreen HMI, 50 recipes

- Covering:

- IP65 dust and humidity proof stainless steel covering AISI 304

- Critical seal parameter recipes:

- Up to 50 recipes can be stored (including machine height when combined with motorized support)

- Downloadable batch information:

- Batch information of critical seal-parameters can be downloaded (USB stick)

- Foot operation:

- Yes

- Configurable to customer specific requirements:

- Yes

- Film type:

- Suitable for sealing various modern film types including thick films and special laminates

- Classification:

- 2014/35/EU Low Voltage Directive, 2006/42/EC Machine Directive. 2014/30/EU EMC-Directive, RoHS 2 2011/65/EU Directive; EN-ISO 11607-2, EN-ISO 12100, EN-ISO 4414, EN-ISO 14118, EN-IEC 60204-1

Explore your options

Customize your Power Sealer PLUS IP65 to your unique requirements

Big bag/Bag-in-Box configuration

Especially designed for sealing and vacuuming big bags in a box or barrel. This innovative option includes convenient hardware modifications such as a large sealing length of 1720 mm, an extra-long wide nozzle and Europallet frame adaption. Software-wise, this option includes the vacuum tube/nozzle lift down to assure optimized vacuuming or gas flushing closest to the product. Resulting in premium vacuum results and product safety.

Optimized seal position

A robust and configurable frame is available to optimize sealing height (infinitely adjustable), sealing angle and maximize ergonomic advantages. Various extra product support options available. When operating the electrical support the ideal sealing height for each product can be set in the sealer’s recipe (software)..

Superb calibration & supervision

Ensure full quality and production control per batch or per employee by specifying password-protected access levels. Professional and timely maintenance or (re)calibration of your (new) machine according to the highest and valid standards.

Wrinkle-free sealing

Provide flawless seals with the convenience of bag stretchers that assist you in keeping the bag properly tensioned during the packaging process.

Discover our Power Sealer line:

This no-nonsense Power Sealer forms the solid basis of the renowned Power Sealer line. The outstanding 5 mm sealing performance is achieved by a pneumatic bi-active and time-controlled impulse sealing system. Optional vacuum system feature can be integrated.

This model is validatable and generates an 8 mm temperature- and time controlled seal. The validation enables that critical seal variables like seal force, seal temperature and seal time are being controlled. Optional vacuum system feature can be integrated.

The Power Sealer TC is a high-performance temperature controlled sealing machine designed for demanding packaging needs in the high-tech and food industries. It features a durable stainless steel housing, touchscreen interface, and powerful bi-active and pneumatic seal bars that ensure consistent, airtight seals. Optional vacuum system feature can be integrated.

The next step in the Power Sealer line is the Plus version. With its unique and most precise system of validation it meets todays' most stringent packaging requirements. 8 mm Temperature- , time- and force controlled seal. Includes Audion Touch Techware. Optional vacuum system feature can be integrated.

Our flagship model in the Power Sealer line. Especially designed for dusty, humid or regulated (clean room) production environments. Highly advanced validatable impulse sealer. An 8 mm temperature-, time and force controlled seal. Includes Audion Touch Techware. Optional vacuum system feature can be integrated. Also available in Bag-in-box configuration.

The Power Sealer TC XL and Power Sealer PLUS XL have the largest sealing length of the Audion Power Sealer range. With a sealing length of 2500 mm they can effortlessly provide your largest products with customized packaging or protective covers by means of an 8 mm seal. Available in a temperature controlled model (PSR TC XL) and a validatable model (PSR PLUS XL) with validation on temperature-, time- and seal force controlled sealing. Optional vacuum system feature can be integrated.

Unique steamsealer enabling bags to be sealed without electrical power supply. Instead, it uses pressurized steam to operate. suitable for explosive environments. 8 mm temperature controlled seal. Optional vacuum system feature can be integrated.

Our Power Sealer PLUS IP65 in use

Available spare parts

Related products

Let's have a chat

Do you want to know what the Audion PSR PLUS IP65 can offer for your company? Please feel free to contact us as we are looking forward to exploring together which packing solutions benefit you most.

International Sales

Audion